October 21, 2011

October 17, 2011

S2 prototype #2 - construction 3

More progress on my second point source horn prototype.

Assembling the second flare section. First they are screwed together to check they are correct. Then glued.

It sits on top to check alignment.

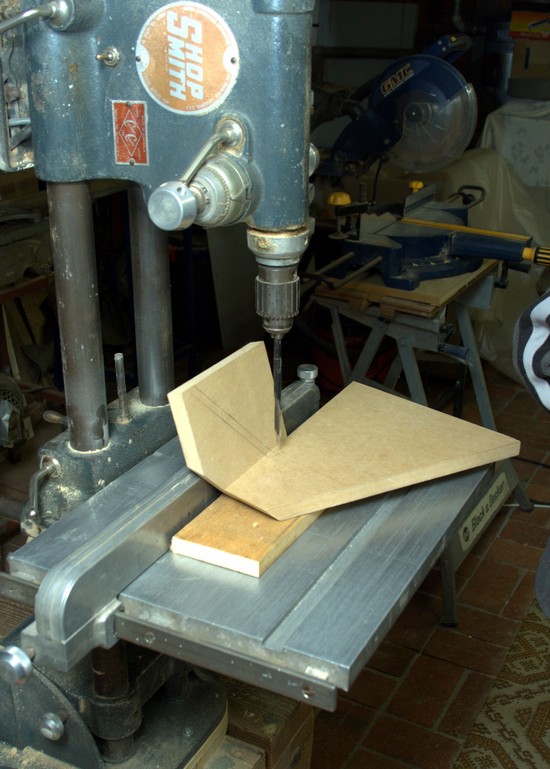

Drilling port holes.

Previously this was done before assembly, but this time I decided to try it the other way. You can see above a test sample. It was drilled from the inside out to actually find the exact location. Obviously drilling on the assembled horn is from the outside in.

Outside in view:

View on the inside:

Now it can be dimensioned:

Filling the joins:

You can see there is quite a bit of patching. Ports have now been drilled:

Assembled horn with mounting baffles:

The mounting for my Miniwaves is also shown on the right.

Horn flare transition has been smoothed:

Baffles added to allow six 5" mids to be added. Ports this time will be 9mm deep, and flaring is required to achieve this.

October 3, 2011

Bass horns in the works

My point source horn project has revealed the magic of horn loading. There is something spectacular about very high efficiency when it is achieved by horn loading. All else being equal, higher efficiency leads to higher fidelity. Why? From the moment more power is applied and diaphragm excursion is increased, we see the increasing effects of thermal and mechanical problems. Power compression and thermal dynamic issues come into play. Mechanical memory effects and nonlinearities increase. Everything gets worse as excursion goes up.

Horn loaded treble

The typical solution for treble is a 1" dome with about 89 dB 1w1m. At levels of about 90 dB in the listening position the sound has degraded considerably, and we are stuck with the very wide dispersion that comes from a small piston and we can't run it low enough that we might cross over where the mid also has wide dispersion - at least not without a complex crossover and many drivers. A 1" exit compression driver will have a 44mm diaphragm and 3x the piston area. We end up with around 109 dB sensitivity and greater thermal power handling due to a larger voice coil. We can also run the crossover down to 1k, at least an octave lower than the dome tweeter. The 20 dB increase in sensitivity means 1% of the power input for a given output level. The sound quality of the compression driver now becomes mostly related to two main things:

1. The way the driver behaves regarding breakup. Titanium units seem to have some issues there while drivers with polyimide and polyester seem to be the most preferred.

2. The design of the horn or waveguide.

The advantages are compelling:

Horn loaded midrange

If you are starting with a compression driver at the top end, then it is easier to get high sensitivity speaker in the midrange without horn loading. You can get 100 dB sensitivity with a pair of 15" pro midwoofers. In fact, even an 8" high sensitivity mid can do very well. However, there is a certain magic in horn loaded midrange as well. In this type of horn in particular, people talk about the ability to reveal low level detail. Sounds not noticed before, buried in the mix start to emerge. I can only guess where this comes from, but I suspect that it relates to a few things. One of them might be the bandpass aspect that acoustically filters out harmonic distortion, leading to greater clarity and less masking of detail. Another could be the ability to use small low mass drivers where cone breakup is well outside the passband. The horn is doing the work so we are relying much less on the motor itself.

Horn loaded bass

This is the area that I now intend to investigate. In the bass range, cone area and excursion as well as motor issues are all very important. I have two projects in the works:

1. Midbass horn 50 - 250 Hz with my current 18" Eminence Magnum driver

2. Sub bass horn with dual opposed Rythmik 12" drivers 15 - 50 Hz.

As direct radiators, the 18" woofers can reach THX levels with some headroom, but it's not so much about output as it is arriving in style. 95 dB becomes more like 105 dB and 50 Hz extension seems possible with a corner design. A further advantage is the bandpass aspect where the horn also has an acoustic filtering function. The main problem is not taking up too much bass trap real estate.

The tapped horn subs increases the efficiency at 20 Hz by 15 dB, since the drivers start rolling off around 40 Hz without EQ. At their top end, the tapped horn adds about 6 dB. As direct radiators, the subs can't keep up with everything else. The problem is not their sound, because they sound fantastic. The amps can overheat when trying to keep up because a lot of power is needed to overcome the low efficiency. So there are two solutions - one is to simply add more of them. The other is to horn load them with a tapped horn and limit their bandwidth. I've chosen the latter - the horn loading increases the excursion limited LF output and the narrower bandwidth also means a less continuous power demand.

I should mention that there is no problem with the Rythmik subs. It's simply asking too much of a pair of 12" subs.

Horn loaded treble

The typical solution for treble is a 1" dome with about 89 dB 1w1m. At levels of about 90 dB in the listening position the sound has degraded considerably, and we are stuck with the very wide dispersion that comes from a small piston and we can't run it low enough that we might cross over where the mid also has wide dispersion - at least not without a complex crossover and many drivers. A 1" exit compression driver will have a 44mm diaphragm and 3x the piston area. We end up with around 109 dB sensitivity and greater thermal power handling due to a larger voice coil. We can also run the crossover down to 1k, at least an octave lower than the dome tweeter. The 20 dB increase in sensitivity means 1% of the power input for a given output level. The sound quality of the compression driver now becomes mostly related to two main things:

1. The way the driver behaves regarding breakup. Titanium units seem to have some issues there while drivers with polyimide and polyester seem to be the most preferred.

2. The design of the horn or waveguide.

The advantages are compelling:

- Virtually unlimited output in a domestic system.

- An effortless and very dynamic sound that allows music to be enjoyed at much greater levels when desired.

- The ability to match the dispersion of the midrange for a smooth polar response transition.

- Flexibility with crossover points - 1k or below is possible

Horn loaded midrange

If you are starting with a compression driver at the top end, then it is easier to get high sensitivity speaker in the midrange without horn loading. You can get 100 dB sensitivity with a pair of 15" pro midwoofers. In fact, even an 8" high sensitivity mid can do very well. However, there is a certain magic in horn loaded midrange as well. In this type of horn in particular, people talk about the ability to reveal low level detail. Sounds not noticed before, buried in the mix start to emerge. I can only guess where this comes from, but I suspect that it relates to a few things. One of them might be the bandpass aspect that acoustically filters out harmonic distortion, leading to greater clarity and less masking of detail. Another could be the ability to use small low mass drivers where cone breakup is well outside the passband. The horn is doing the work so we are relying much less on the motor itself.

Horn loaded bass

This is the area that I now intend to investigate. In the bass range, cone area and excursion as well as motor issues are all very important. I have two projects in the works:

1. Midbass horn 50 - 250 Hz with my current 18" Eminence Magnum driver

2. Sub bass horn with dual opposed Rythmik 12" drivers 15 - 50 Hz.

As direct radiators, the 18" woofers can reach THX levels with some headroom, but it's not so much about output as it is arriving in style. 95 dB becomes more like 105 dB and 50 Hz extension seems possible with a corner design. A further advantage is the bandpass aspect where the horn also has an acoustic filtering function. The main problem is not taking up too much bass trap real estate.

The tapped horn subs increases the efficiency at 20 Hz by 15 dB, since the drivers start rolling off around 40 Hz without EQ. At their top end, the tapped horn adds about 6 dB. As direct radiators, the subs can't keep up with everything else. The problem is not their sound, because they sound fantastic. The amps can overheat when trying to keep up because a lot of power is needed to overcome the low efficiency. So there are two solutions - one is to simply add more of them. The other is to horn load them with a tapped horn and limit their bandwidth. I've chosen the latter - the horn loading increases the excursion limited LF output and the narrower bandwidth also means a less continuous power demand.

I should mention that there is no problem with the Rythmik subs. It's simply asking too much of a pair of 12" subs.

October 2, 2011

S2 prototype - construction 2

More progress on my second point source prototype.

Tools I couldn't do without:

You see two sets of calipers. The top set find the dimensions of the throat, which can then be measured with the calipers. There is also an angle tool which gets used a lot with a project like this.

This is a "buzzer." It's a fixed plane with a fence that can be angled. It's good for planing down rough timber edges quickly, but it can also do angles. Most of the angles for the horn were done on the buzzer.

Shop smith. It's a multi-purpose tool - table saw, drill press, wood lathe and sanding disc all in one. In this project it functions mostly as a table saw, few of the angles are best done with this tool.

You may have noticed the throat has some interesting things going on. This is where it gets fixed. The table on the shop smith is angled as shown and the horn is clamped on. See below. Now the sanding disc is pressed into the throat until it comes out nice and flat.

Like this:

With the different angles involved here, I need a different mounting system. A flange will mount to the horn, then an acrylic sheet makes it all work. You can't attach the compression driver to the flange as the drivers are in the way.

The flange and mounting plates are fixed together and then I find the centre point, marked with a punch. You can see the holes in the acrylic sheet already drilled.

A very large drill bit comes in handy:

The second flare section is a little more difficult to get right. Parts are screwed together so that I can see they will fit together. It's not possible to hold them together correctly, not even with two people.

Four pieces assembled with screws:

Blocks were used in the corners to help with alignment. The edges of these were precisely angled.

Second flare angle sitting on top to check alignment:

The horn is bigger than it might appear. Overall width is around one metre!

October 1, 2011

S2 prototype - construction

The first day of building was cutting sheets. This is day two. All pieces cut:

16 in total

They are assembled mouth down and it's a two person job. First I drill and screw to check everything fits well enough. Then I glue the panel you see in front first, then the other side. With the screws holding it together, there is no need for clamps. I can also work on them immediately with no waiting.

The glue is still setting on this one; while that's happening I'm about to cut off the corners with a hand saw.

This is the result at the end of the day:

All the sheets need to line up on the inside edge. The assembled horn will be placed onto the shop smith next time, the table will be angled down 22.5 degrees (half of the vertical coverage angle). Then I will trim the apex flat with a sanding disc on the shop smith. This is a good way to get them all to line up nicely. Without the shop smith, each one would need to be done individually, taking much longer.

Coming up:

- second flare section

- compression driver mounting plate (already half done)

- mid mounting arrangement (still will need to be worked out partially at the time)

September 28, 2011

September 20, 2011

B&C DE250 1" compression driver - looking inside

Previously I introduced the B&C DE250 as a great value good sounding compression driver. I have since had more time to use this driver in various projects, and I've also taken it apart and measured its dimensions carefully to understand how to design a waveguide for it as part of my point source horn project.

You can see it's seen some action already. You can also see the gap around the exit tube (right). You can see the concentric slots on the phase plug (left). Then you can also see the VC gap.

Overall, this driver could have been made better. The diaphragm lacks a spigot to centre the VC so there is no way to be sure that you have it positioned correctly. This could well mean a bigger than necessary VC gap to allow for this. Far better to simply design it to centre the VC so that you can't get it wrong. The exit tube gap is quite poor as well. Despite these complaints, it's a very good sounding driver and I put that down to the polyimide diaphragm which is well damped and the fact that overall it's well designed in terms of its acoustic performance. The response is smooth and flat and I'm yet to hear a better sounding compression driver.

See also

BMS 4550

Faital pro HF10TX

This section shows what I was able to measure. I didn't have access to everything, so there is some guesswork with the phase plug and pole.

Most of this is just the standard compression driver design that has mostly remain unchanged for a very long time. The phase plug has concentric slots and a conical exit tube. I estimate a 12 degree included angle on the exit tube. It was difficult to measure accurately and I believe Earl Geddes has stated that it is in fact 6.5 degrees to the normal (13 degree included angle). The phase plug (shown in purple) is a one piece cast plastic unit. There is a gap at the end that is significant and should be filled when mounted.

This rear cap comes off when the diaphragm needs replacing:

It appears to be cast aluminium and there is a small amount of foam. Tweakers might like to add some more material here, although it's difficult to get much in before crowding the small space. For critical applications I'd like to see a much bigger chamber with a lot more foam.

Diaphragm front and rear view. It's a 44mm dome with a copper voice coil and flat ribbon lead in wires. This is a second hand unit, the usual spring terminals have been replaced with a soldered cable. The previous owner apparently has a tendency to tweak everything.

You can see it's seen some action already. You can also see the gap around the exit tube (right). You can see the concentric slots on the phase plug (left). Then you can also see the VC gap.

Overall, this driver could have been made better. The diaphragm lacks a spigot to centre the VC so there is no way to be sure that you have it positioned correctly. This could well mean a bigger than necessary VC gap to allow for this. Far better to simply design it to centre the VC so that you can't get it wrong. The exit tube gap is quite poor as well. Despite these complaints, it's a very good sounding driver and I put that down to the polyimide diaphragm which is well damped and the fact that overall it's well designed in terms of its acoustic performance. The response is smooth and flat and I'm yet to hear a better sounding compression driver.

See also

BMS 4550

Faital pro HF10TX

Subscribe to:

Posts (Atom)