More progress on my second point source horn prototype.

Assembling the second flare section. First they are screwed together to check they are correct. Then glued.

It sits on top to check alignment.

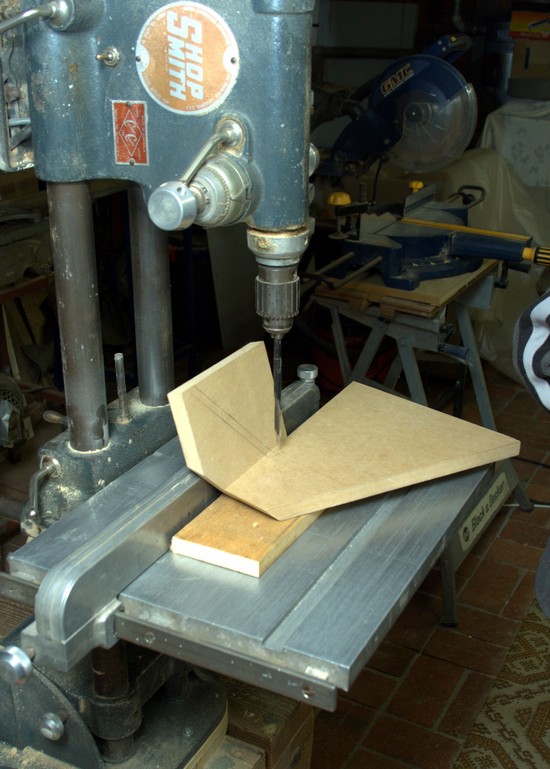

Drilling port holes.

Previously this was done before assembly, but this time I decided to try it the other way. You can see above a test sample. It was drilled from the inside out to actually find the exact location. Obviously drilling on the assembled horn is from the outside in.

Outside in view:

View on the inside:

Now it can be dimensioned:

Filling the joins:

You can see there is quite a bit of patching. Ports have now been drilled:

Assembled horn with mounting baffles:

The mounting for my Miniwaves is also shown on the right.

Horn flare transition has been smoothed:

Baffles added to allow six 5" mids to be added. Ports this time will be 9mm deep, and flaring is required to achieve this.

Keep the excellent work coming Paul, I don't comment regularly but I keep up with all your updates! Would love to hear sometime when I'm back from overseas!

ReplyDeleteHi Paul,

ReplyDeleteHave you considered making a mould and fibreglassing the horn? You would be able to get a closer to perfect shape of the horn. Also you could epoxy in strips of thin mdf of other materials to get the density, wieght and strength right up there.

The shape of the mould is simple and shoule be easy to pop off the mould, possibly easier using a bike tyre valve at the narrow section and using compressed air to 'pop' the first intial fibreglass off the mould, then add layers after this.

Of course you will still need to be fairly craft to mount the drivers.

Thanks for the suggestion Adam. Fibreglass was an option I was talking about recently while working on the above. I'm not sure it would actually be easier for a one-off.

ReplyDelete